Thüringer Bergbahn: how it operates

The Thüringer Bergbahn is made up of two sections:

- The funicular railway between Obstfelderschmiede and Lichtenhain

- The upland route between Lichtenhain and Cursdorf

When the contract to build a rail line was announced, the connection had to run between Obstfelderschmiede and Cursdorf, i.e. the funicular was an integral part of the route from the very beginning. Today, the line bears the number 6691 in Deutsche Bahn AG's system.

The funicular section uses two different vehicles: a passenger carriage with a stepped interior, and a freight platform. The latter can carry railway wagons with a standard gauge and total mass of 27 tonnes.

Its original purpose was to carry freight between the upland around Oberweissbach and Germany's nationwide rail network.

Since the 1970s, the freight wagon on the freight platform has mostly been replaced by a closed passenger carriage, or from May to October, by an open-top carriage – our "convertible" – when the weather is good.

The single-track line uses an Abt-style switch halfway along the route to let the vehicles pass each other. Another Abt switch at the valley station splits the line into two tracks, one leading to the platform for the passenger carriage, the other to the loading ramp for the freight transporter.

There is a turntable at each terminus, giving the line a connection to the larger rail network with its standard-gauge tracks.

Combined, these features have created a funicular railway like no other in the world. Still fully operational today, it is a living monument to technological ingenuity.

Thüringer Bergbahn: technical data

Planning and overseeing the overall system: Dr Wolfgang Bäseler

Planning and construction of funicular components: Heckel, Saarbrücken, Germany

Original technical data:

|

Type: |

|

Single-line funicular railway with 2 vehicles and Abt switches |

|

|

Length: |

|

1,387.8 m (0.9 miles) |

|

|

Track gauge: |

|

1,800 mm (standard gauge: 1,435 mm) |

|

|

Vertical distance: |

|

|

|

|

Altitude of valley station: |

|

340.8 m above sea level |

|

|

Altitude of summit station: |

|

663.8 m above sea level |

|

|

Gradient: |

|

23.92 ... 25% |

|

|

Speed: |

|

1.6 m/s (5.76 km/h) |

|

|

Journey time: |

|

18 min |

|

|

Cable diameter: |

|

40 mm (nominal diameter) |

|

|

Diameter of drive pulleys: |

|

4,000 mm each (of 2) |

|

|

Wrap angle at drive pulleys |

|

270° (x2) = 540° total wrap angle

|

|

|

Rotational speed of drive pulleys at 1.6 m/s: |

|

7.64 rpm |

Drive system: Two asynchronous three-speed motors and two drivetrains

- 110 kW, 3 x 400 V each

- Max. 935 rpm

Gearing:

- Two units four-stage spur gear and two drivetrains

- Total gear ratio i = 122.34

Cable:

- Diameter = 40 mm

- Six strands with 25 wires each (incl. six cored wires)

- Compacted with polypropylene inserts

- Right-hand lang lay

- 6.28 kg/m

Maschinarium – the heart of the funicular railway

Our machinery room, located in the machine house, houses the funicular's drive system consisting of the following main components:

- Two asynchronous three-speed motors producing 110 kW each, which move the sheave wheels via the drivetrain. An electronic management unit handles synchronisation.

- The two sheave wheels are mounted at a right angle to the direction of travel, so two deflecting pulleys change the orientation. The sheave wheels and deflecting pulleys are all four metres in diameter. Large loads (freight) can only be moved thanks to this space-saving configuration with the maximum cable wrap angle, thereby producing a substantial contact surface between the cable, the surface of the cable groove and the sheave wheel.

Operating brake and security brake, both of which function as a spring-loading brake. The brakes open hydraulically.

Abt switches – the funicular's special switch system

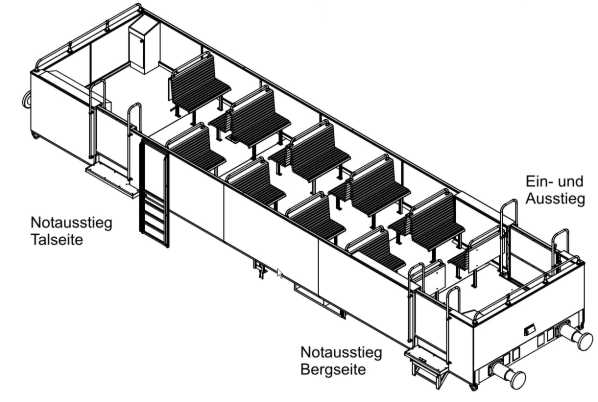

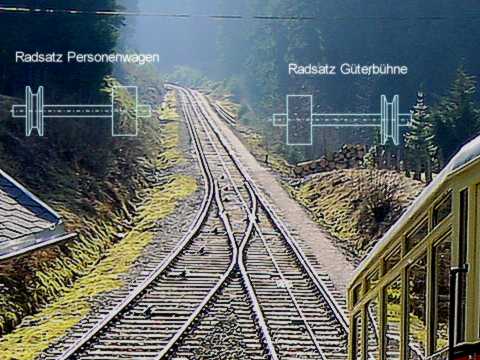

Abt switches have no moving parts. The passenger carriage has double-flanged wheels on the left-hand side, and it is guided by the left-hand rail. Its roller wheels on the right can simply pass over the cable gap in switch. On the freight platform, the wheel positions are reversed. It is guided by the right-hand rail, while its roller wheels are located on the left.

.

The switch type is named after its inventor,

Carl Roman Abt (born 16 July 1850 in Bünzen, died 1 Mai 1933 in Lucerne) was a Swiss engineer, inventor and entrepreneur. He came up with several ground-breaking solutions, such as the Abt system that applies cog and adhesion power for rack railways, and the "self-steering" switch used at Oberweissbach. In addition, he also oversaw the construction of 72 mountain railways around the globe, with Visp-Zermatt, Gornergrat, Furka and Monte Generoso being just some of his projects.

(Photo and information sourced from Wikipedia)

Vehicles on the funicular railway

Passenger carriage

The passenger carriage, called "Wagon 1" by the funicular's crew, has undergone only minor modifications since the line opened in 1923. The changes were made at both ends, which were given a curved shape and larger windows. Reconstruction work in 2002 saw the addition of a platform for bicycles. It is attached to the chassis and offers space for 8 bikes.

Technical data

|

Length |

9.66 m (without bicycle platform) |

|

Width |

3.93 m (without steps and handgrips) |

|

Height above top of rail |

4.08 m (varies due to suspension) |

|

Dead weight |

26 t (empty, unloaded) |

|

Payload |

7.5 t (100 people at 75 kg each) |

|

Normal weight |

33,500 kg |

|

Seats |

42 |

|

Standing room |

58 |

Freight platform with closed carriage

Called "Wagon 2", the freight platform is at the other end of the cable and was originally the most important part of the funicular. It was specially designed to carry freight wagons, but different kinds of passenger vehicles can also be mounted on it, a practice which started as long ago as 1923. This flexibility makes the Thüringer Bergbahn’s funicular unique. Today, the freight platform can carry either our closed or open-top wagon. These are the platform's usual loads, as it transports a freight wagon only when we give a demonstration.

All of the controls are in the platform itself, which means it can also work without carrying a carriage and simply transport employees.

The closed carriage has been in use since 1972. A trailer wagon for the electric-powered railcar operating on the Schleiz-Saalburg line, its number is EB 188 513. It was altered for deployment on the funicular railway and sliding steps were fitted so that it reached the step-shaped platform at the Lichtenhain summit station, where the gap was about one metre. The 2002 reconstruction was intended to return it largely to its original form, but it also entailed installing an emergency escape ladder on one side in line with passenger safety requirements for funicular railways.

Technical data

|

Length |

10.3 m |

|

Width |

2.56 m without brake shaft |

|

Height above top of rail when carrying wagon |

Up to 9 m (restricted by entrance to summit station's 9.11 m above top of rail) |

|

Freight transporter's unloaded weight |

25,000 kg |

|

Freight transportation: |

|

|

Passenger transportation with closed carriage: Empty carriage Max. load Total weight Seats Standing room |

5,400 kg (72 people weighing 75 kg each) 39,600 kg 32 40 |

Freight platform with open-top carriage

Our "convertible" was fashioned from a service car that was once part of a construction works train, and now functions as the funicular railway's open-top carriage. "Wagon 3", as it is known, is designed to be mounted on the freight platform the same as the closed-top carriage. The fact that the Thüringer Bergbahn was designed to transport normal railway wagons – the only one in the world to do so – is what makes it possible to use these two carriages for transporting people. The open-top wagon is considerably longer than its closed-top mate, so it projects much further over the edge of the transporter platform. This means that passengers are even higher above the level of the tracks below, giving them an even more impressive view of their surroundings.

It is in use during good weather from May to October. Due to its structure, it does not operate if rain or thunderstorms are forecast.

Technical data

|

Length |

11.27 m |

|

Width of frame |

2.38 m |

|

Seats |

38 |

|

Standing room |

65 |

|

Payload |

8.2 t |

|

Wheelbase |

6.8 m |

|

Length over buffers |

12.7 m |

|

Freight transporter's unloaded weight |

25,000 kg |

|

Passenger transport with the convertible Empty Max. load Normal weight |

7,725 kg (103 people at 75 kg each) 42,945 kg |

|

Seats |

38 (without special features) |

|

Standing room |

65 (without special features) |